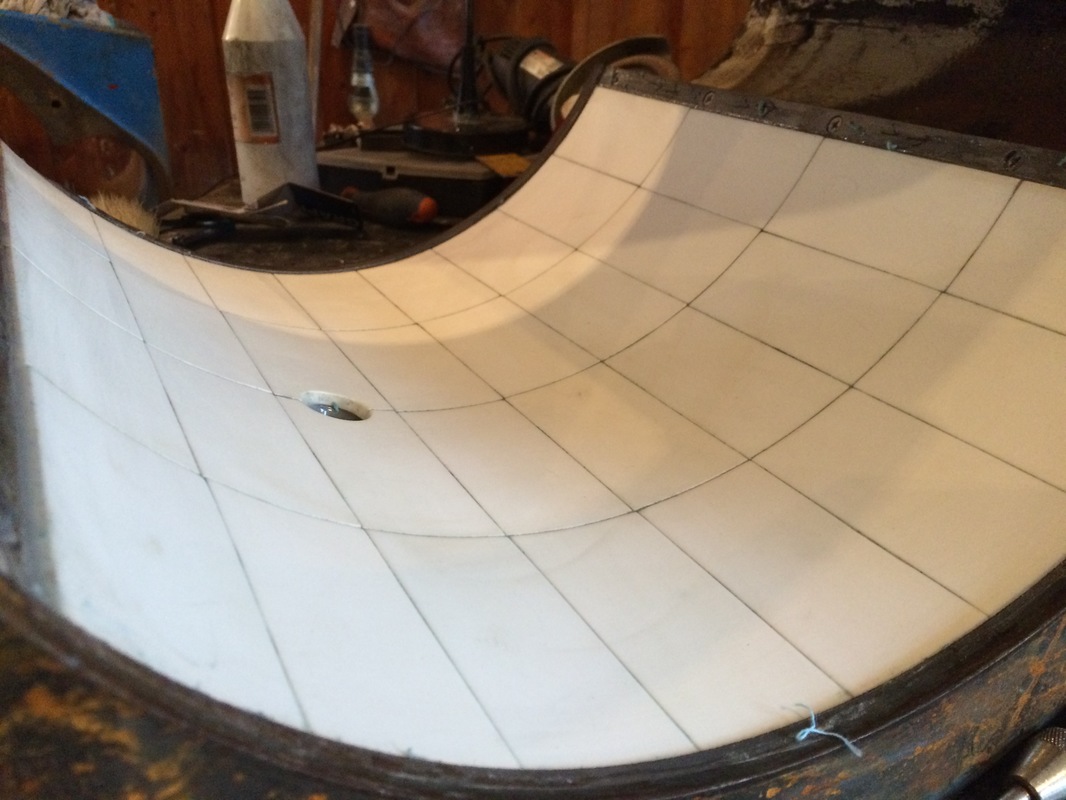

Pneumatic or hydraulic transport of the media such as ash, slag, coal dust or alternative fuels (biomass) requires the preparation of certain elements of pipelines such as distributors/manifolds, bends or diffusers in a special way. These are places of installation most exposed to abrasion/detrition. The best solution offered in the market are elements lined with ceramics. Applying/use of our solution provides several times longer inter-renovation periods.

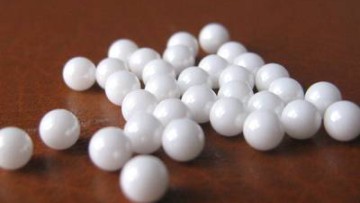

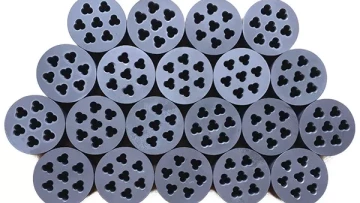

Our ceramic materials used on abrasion-resisting lining consist of min. 92% of pure aluminium oxide, are pressed at a pressure of up to even 200 MPa and are sintered at a temperature of 1600ºC. Our linings are mounted on the binder/binding agent of own idea/invention, which has excellent adhesive properties for ceramics and metal, and, in addition, is also abrasion-resisting.

Abrasion-resisting linings we make for:

- power plants

- cement mills (cement plants)

- papermills (paper factories)