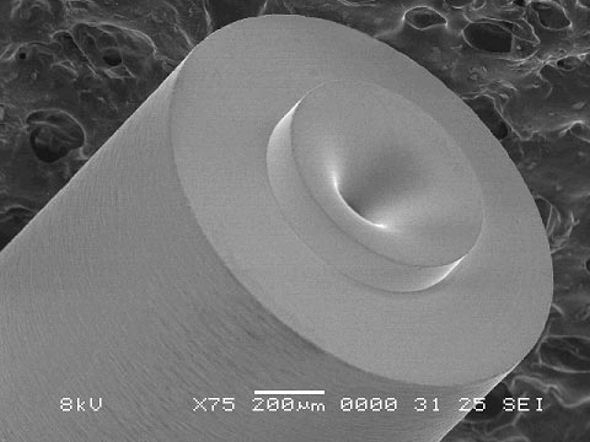

CIM (Ceramic Injection Moulding) or high-pressure injection molding of ceramics - is a technology that allows you to obtain of ceramic microparts with a very complicated (complex) shapes and very narrow tolerances.

Experience, equipment resources and production capacities of ceramic materials by the SPT company allow you to achieve the repeatable parts with an accuracy of +/- 0.001 mm. This puts SPT among the world leaders in this field.

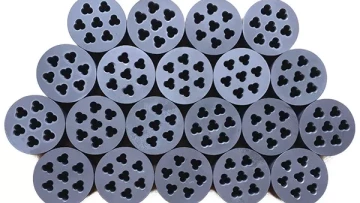

Ceramic parts made by injection molding are often used in industry:

- textile - guides

- electronics - capillaries, nozzles, insulators, guides, screws

- chemical - nozzles, mixing valves, other

- medical - bio-compatible parts of medical equipment and implants

- dental - transparent fastenings/fixations of tooth crowns, dental screws

- watchmaking - wear-resistant mechanical microparts