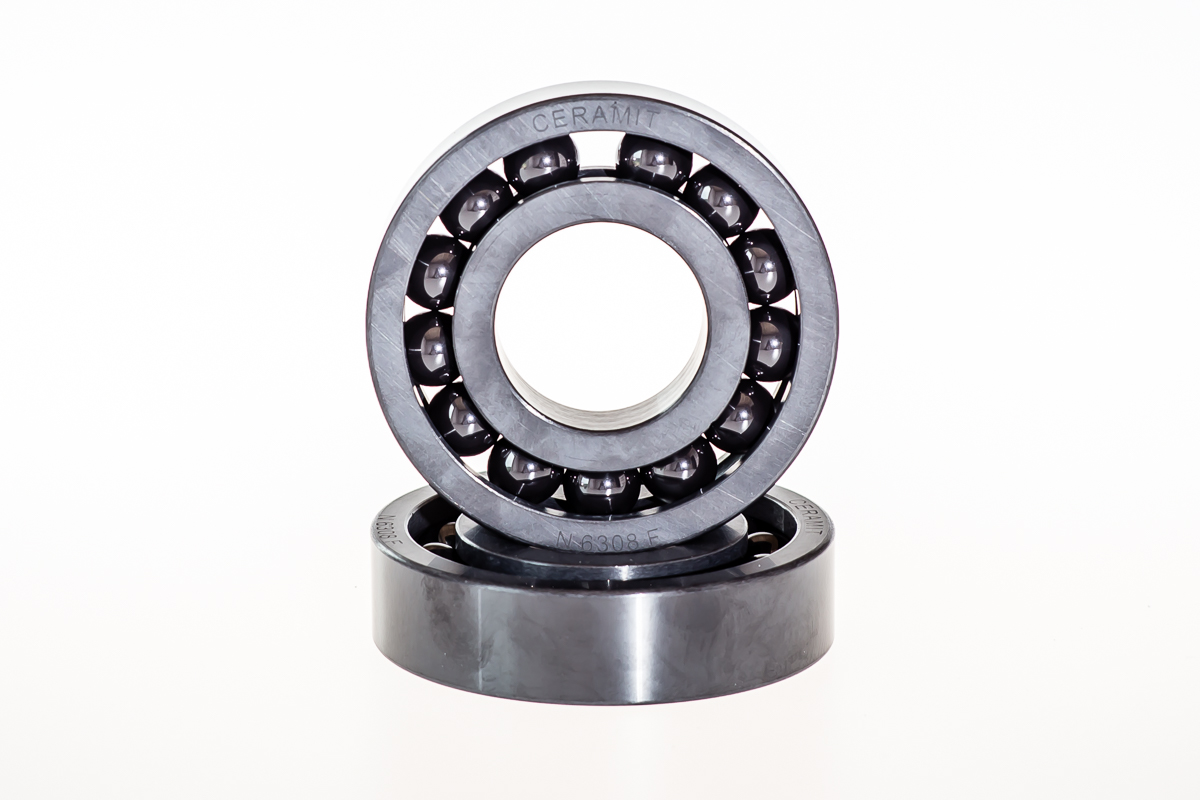

Ceramic bearings

Ceramic bearings are such bearings, which races/raceways and balls are ceramic. If these bearings run at temperatures up to a maximum 300ºC, then these are equipped with cage (bearing spacer, bearing retainer) made of plastic, and above this temperature occur in a special version without cage.

Ceramic bearings are applicable everywhere there where is required:

- corrosion resistance

- high or low temperature

- no magnetic properties

- electrical insulation

- lack of lubrication

Hybrid bearings

The bearings, which the rolling elements are made of ceramics we call hybrid bearings. Races/raceways of hybrid bearings, depending on the application, are made of chromium steel or stainless steel. The most commonly used material for the rolling elements is silicon nitride. Cages, seals and shields are made from similar materials as in the case of traditional bearings (steel bearings).

Properties of bearings of this type:

- extended service life - can with-stand up to 5 times longer than steel bearings

- low weight of the rolling elements - silicon nitride is three times lighter than steel

- very low rolling resistance - even by 70% lower rolling resistances

- ceramic rolling elements - do not corrode, are not magnetic, are very hard and abrasion-resistant

- the maximum rotational speed - to 500,000 rpm

- insulating power - the rolling elements isolate raceways/races one to each other (it doesn't concern bearings with shields of type ZZ)

Bearings of plastics

The best bearing is such, that is matched to the conditions of operation. Therefore, were created ceramic bearings both hybrid and of plastics. For the production of the latter are used such materials as POM (polyoxymethylene), PTFE (polytetrafluoroethylene/Teflon) and PEEK (polyethepetherketone).. Rolling elements in this type of bearings are made in turn from such materials as: glass, stainless steel or ceramic. These bearings are characterized by:

- low curb weight (tare weight)

- high chemical resistance

- the possibility to work in immersion

- low price

Available types and sizes of bearings:

- Deep-groove ball bearings - 60.., 62.., 63.., 64.., 69.., 68.., 6.. series

- Angular-contact ball bearings - 70.., 72.., 73.., 78.., 79.. series

- Self-aligning ball bearings - 12.., 22.., 13.., 23.. series

- Thrust ball bearings (thrust bearings) - 511.., 512.., 513.., 514.. series

- Bearings in the self-aligning housing - UC2.. series

You do not know, what bearing should use? Contact us for more information. We will select the best bearing for your application.

Ceramic slide bearings (plain bearings)

Using such properties of ceramics as corrosion resistance and wear resistance, it is used successfully for the manufacture of slide bearings. Most frequently these bearings are submerged, where the medium is lubricant for bearings. The bearings are manufactured according to individual projects.

We deliver bearings for such industries as:

- food products

- pharmaceutical

- metrological

- mechanical engineering

- recycling

- cosmetic

- pwoer engineering

- sports

- aviation